You have no items in your shopping cart.

0

You have no items in your shopping cart.

| Stretch | 1.80% @ 6kN |

| Material | Vectran & UHMWPE |

| Weight | 31 g/m (2.08 lbs/100 feet) |

| MBS | 38.0 kN (8,542 lbf) |

| WLL | 12.6 kN (2,847 lbf) |

| Width | 20.0 mm (0.79 inches) |

Style

Best Tension

Introducing the all new Spider Silk MK3, a new kind of HiTech webbing for long and highline use.

This webbing is unique in it's construction with a combination of Vectran and UHMWPE fibers mixed together for an optimized weave pattern that offers superior strength, stretch, and durability for the demanding project lines that it's intended for.

Not only does this webbing have a unique construction, it also comes in at 20mm in width! This helps with wind as it has 20% less surface area for the wind to capture on big lines. This will be especially noticeable for lines greater than 300m.

The beauty of high-tech webbing is that it can be so incredibly lightweight while still retaining a great amount of strength. We packed just about as much strength as we possibly could into this small webbing.

A typical low-tech webbing made from Nylon or Polyester will hover around a 0.55 strength to weight ratio. Spider Silk MK3 comes in at 1.22! That is insane! Never has such a light webbing been able to boast such a high strength before. What a way to make your line as easy as possible to walk without compromising on the integrity or burlyness.

Wind is a serious problem on longer highlines. Flat (or even tubular) webbing acts as a sail to the wind that is flowing over a highline. This can cause major problems if the winds are high enough. Tapes start to rip, lines start flapping, and the main and backup start smashing into each other. This can lead to a complete highline failure, as we have seen many times in many places.

One way to look at how wind interacts with the slackline is to look straight down. Given a set length, there is a certain amount of surface area that the slackline has over that length (length x width) Given that we are all going for longer and longer lines, this surface area is bound to get larger as our lines grow. The larger the surface area, the more the wind will hit your line. So, what if we reduce the width instead?

We played with a number of difference widths and found that 20mm is a nice sweet spot for still providing a stable platform on which you can stand/walk, while still reducing the overall surface area of webbing exposed to the wind. The 20mm era is upon us!

High-tech webbings are fantastic for monster lines, mainly due to the weight and strength that they provide. Also because of their stretch! Spider Silk MK3 is no exception to that rule. With a mere 1.8% at 6 kN, this stuff hardly stretches at all! Spend as little time tensioning as you can, so you can get to walking that monster PR line you're bound to rig with this stuff!

Due to the very low stretch of Spider Silk MK3, it is recommended to only use it for highlines longer than 100m.

Compare the stretch of Spider Silk MK3 to our other webbings on our Webbing Stretch page

A feature of Spider Silk MK3 that sets it apart from most other high-tech webbings is the Pillowed Edges. The internals on the edge contruction are made from 100% nylon fibers which stay loose even when the webbing is under tension. This allows the edges to be pliable and malleable while the line is tight, which gives the edges a pillow-feel, molding under your hands and feet when you grab and walk on the line. This feature makes Spider Silk MK3 a true pleasure to interact with.

Given the extreme stretch difference between Nylon and Vectran/UHMWPE, the pillowed edges are very effective on Spider Silk MK3. They are amazingly pliable when the line is tight and conform to your hand and foot quite nicely in use.

The Blue and Black fibers in Spider Silk MK3 are made from a special UHMWPE fiber, which provides very good abrasion resistance. The tan fibers on the faces are made from Vectran, which also offers extreme abrasion resistance.

The fiber selection combined with the weave pattern gives Spider Silk MK3 an extreme durability unmatched in the high-tech webbing world. If you are going big, you may as well make that line as durable as possible as it's likely to stay rigged for a while :)

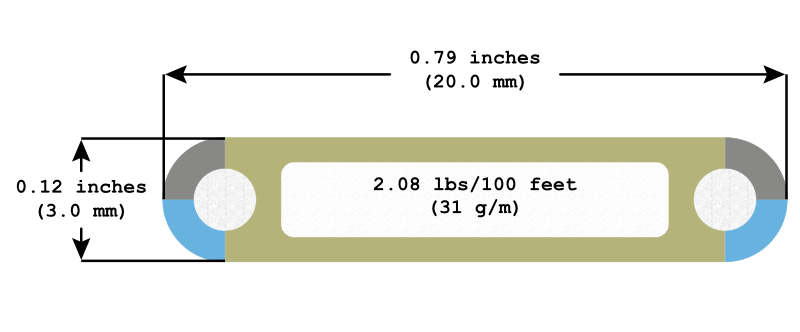

Width – 20.0 mm (0.79 inches)

Thickness – 3.00 mm (0.12 inches)

Weight – 31 g/m (2.08 lbs/100 feet)

MBS – 38.0 kN (8,542 lbf)

WLL – 12.6 kN (2,847 lbf)

AWL4 Mean Strength – 27.6 kN (6,204 lbf)

AWL4 MBS – 26.2 kN (5,890 lbf)

AWL5 Mean Strength – 24.8 kN (5,575 lbf)

AWL5 MBS – 23.8 kN (5,350 lbf)

AWL6 Mean Strength – 32.1 kN (7,216 lbf)

AWL6 MBS – 30.0 kN (6,744 lbf)

MightyLock Mean Strength – 27.6 kN (6,204 lbf)

MightyLock MBS – 25.6 kN (5,755 lbf)

LineGrip Slippage – No slippage up to 150% of WLL (22 kN)

Wafer XL Slippage – No slippage up to 150% of WLL (15 kN)

Wafer Slippage – No slippage up to 150% of WLL (6 kN)

Mean Strength – 34.7 kN (7,800 lbf)

MBS – 33.2 kN (7,463 lbf)

Thread Type – 208-lb Bonded Polyester

Raw Materials – Hybrid Blend - UHMWPE and Vectran

Weave Structure – Flat Weave with Pillowed Edges

Weave Zoning – Four-Zone Construction with Strength, Protective, Bi-Color, and Pillowed zones

Style – Optimized for walking big lines with relative ease

Optimum Tensions – 1.0 - 4.5 kN (225 - 1,000 lbf)

Preferred Lengths – 100+ m (330+ feet)

1 kN – 0.37%

2 kN – 0.78%

3 kN – 0.93%

4 kN – 1.09%

5 kN – 1.21%

6 kN – 1.8%

7 kN – 1.87%

8 kN – 1.93%

9 kN – 2.21%

10 kN – 2.36%

11 kN – 2.36%

12 kN – 2.67%