You have no items in your shopping cart.

0

You have no items in your shopping cart.

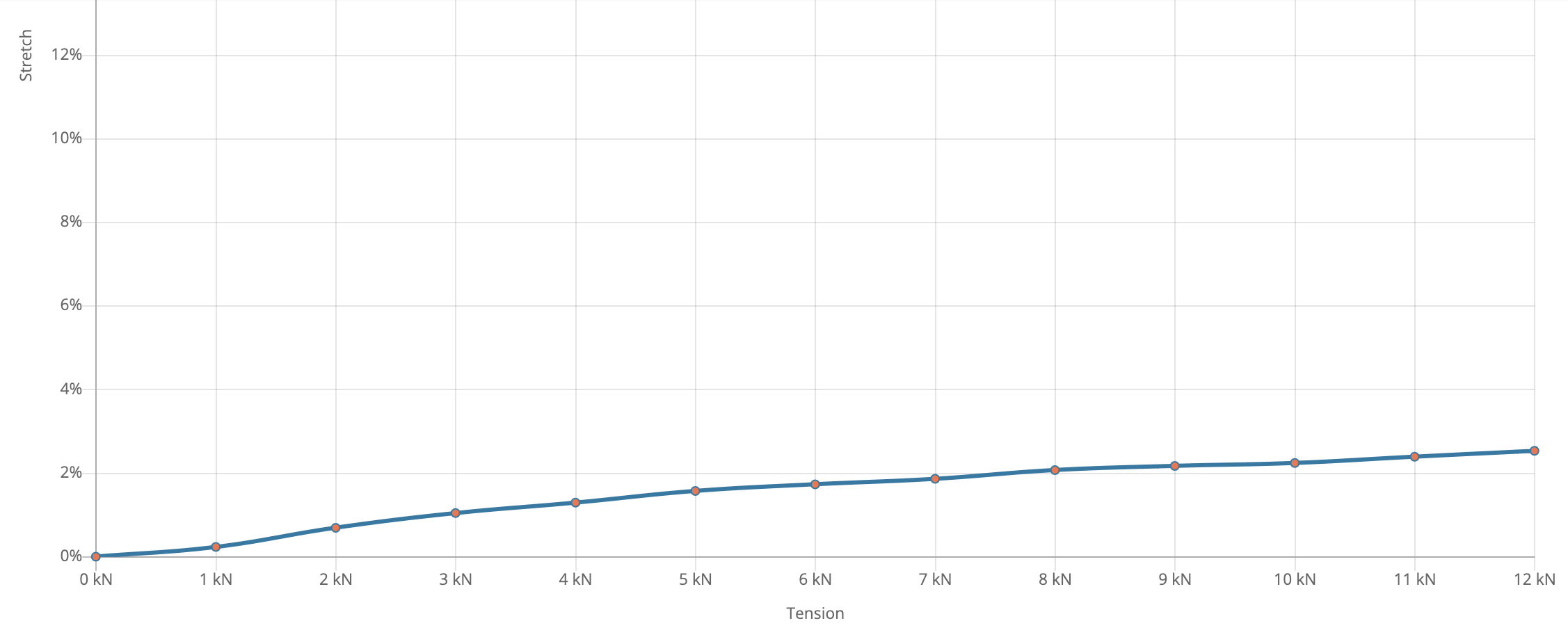

| Stretch | 1.73% @ 6 kN |

| Material | Dyneema SK99 & Black HMPE |

| Weight | 19 g/m (1.28 lbs/100 feet) |

| MBS | 40.0 kN (9,000 lbf) |

| WLL | 13.3 kN (3,000 lbf) |

Style

Best Tension

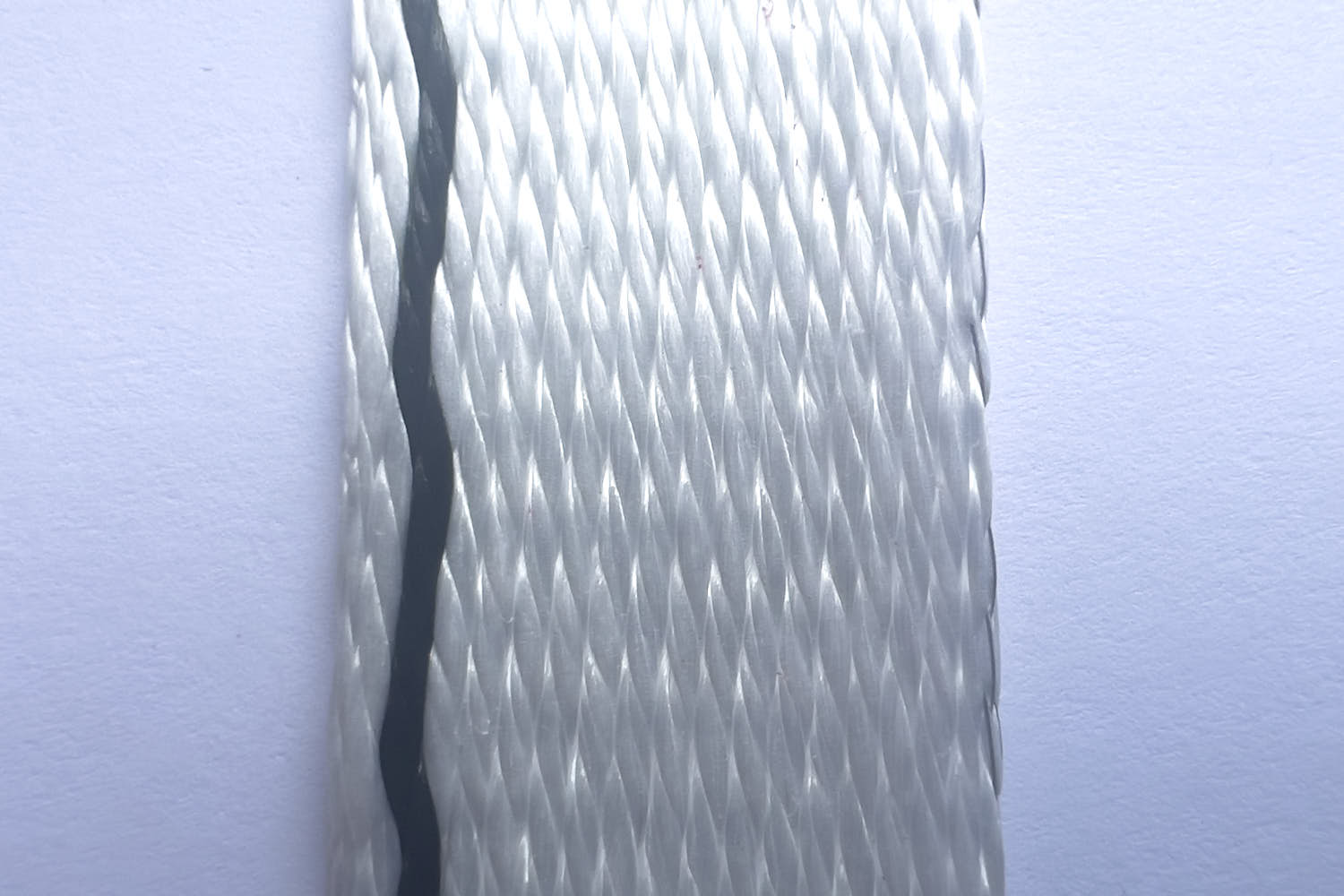

Silk 99 is an extremely lightweight, supremely strong, high-tech webbing built for giga-lines. Its extremely low weight design is perfect for those monster gaps where weight is everything - or for those shorter big lines where a cruiser walk is a necessity. This webbing provides increased strength and stability with no extra bulk, making it an ideal choice for the avid big-liner.

Silk 99 clocks in at a mere 19 grams per meter and a staggering 40 kN MBS with a width of 19 mm. These remarkable specs are in large part due to the use of Dyneema SK99, the strongest iteration of the strongest fiber in the world.

In addition to remarkable specs, Silk 99 offers enhanced creep characteristics, which has recently become more of an issue in the big-line world, where a piece of webbing will gradually grow with more and more usage. Dyneema SK99 has enhanced creep performance in comparison to lower grade Dyneema's, which gives Silk 99 a much more stable measurement, even with excessive usage.

Read more about this incredible webbing below in our Details section.

Made in the US

For your sewn loop selection, please see the sewn loop details listed below.

For custom configurations, main/backup combos, or large orders, please reach out to us for a custom quote.

Silk 99 clocks in at 19 grams per meter and a staggering 40 kN MBS. That gives a strength-to-weight ratio of 2.1! Unheard of...this is a new level of strength-to-weight in the slackline world. This is the first webbing to offer a 2:1 ratio of strength in kilonewtons to grams-per-meter. This is achieved in large part due to the material we chose to use for this webbing: Dyneema SK99.

Dyneema is already the strongest fiber in the world. However, there are many grades of Dyneema, each with their own benefits. One such grade of this amazing material is Dyneema SK99. This particular grade offers the highest strength of any grade of Dyneema, coupled with incredible creep performance. These two features alone make Dyneema SK99 the perfect fiber for an extreme performance webbing like Silk 99.

Another contributing factor to the extreme strength-to-weight performance of Silk 99 is the fact that the webbing contains zero low tech fibers. This webbing is made up of pure Dyneema SK99 plus a few ends of black HMPE.

Not only does this pure High Tech approach bring amazing weight and strength, it also means Silk 99 floats! Both Dyneema SK99 and HMPE are less dense than water, thus they will float indefinitely! That makes Silk 99 superb for waterlines!

Silk 99, being a pure high tech webbing, stretches very little. In our testing, we played with different length extenders on a 100m segment. First we started with 6 meters, which is pretty typical for most high tech rigs. This length of extra for the backup was WAY too much. We easily cut off 2 meters and still had plenty of backup in the system to have nice damping loops.

In the end, we found 5% extra for the backup to be a good sweet spot for most rigs. If you are going very high tension (beyond 4 kN), 5.5% would be more ideal.

Due to the very low stretch of Silk 99, it is recommended to only use it for highlines longer than 200m. Anything lower than this, we would recommend the addition of a nylon segment of 15m or longer at either end of the line.

Compare the stretch of Silk 99 to our other webbings on our Webbing Stretch page

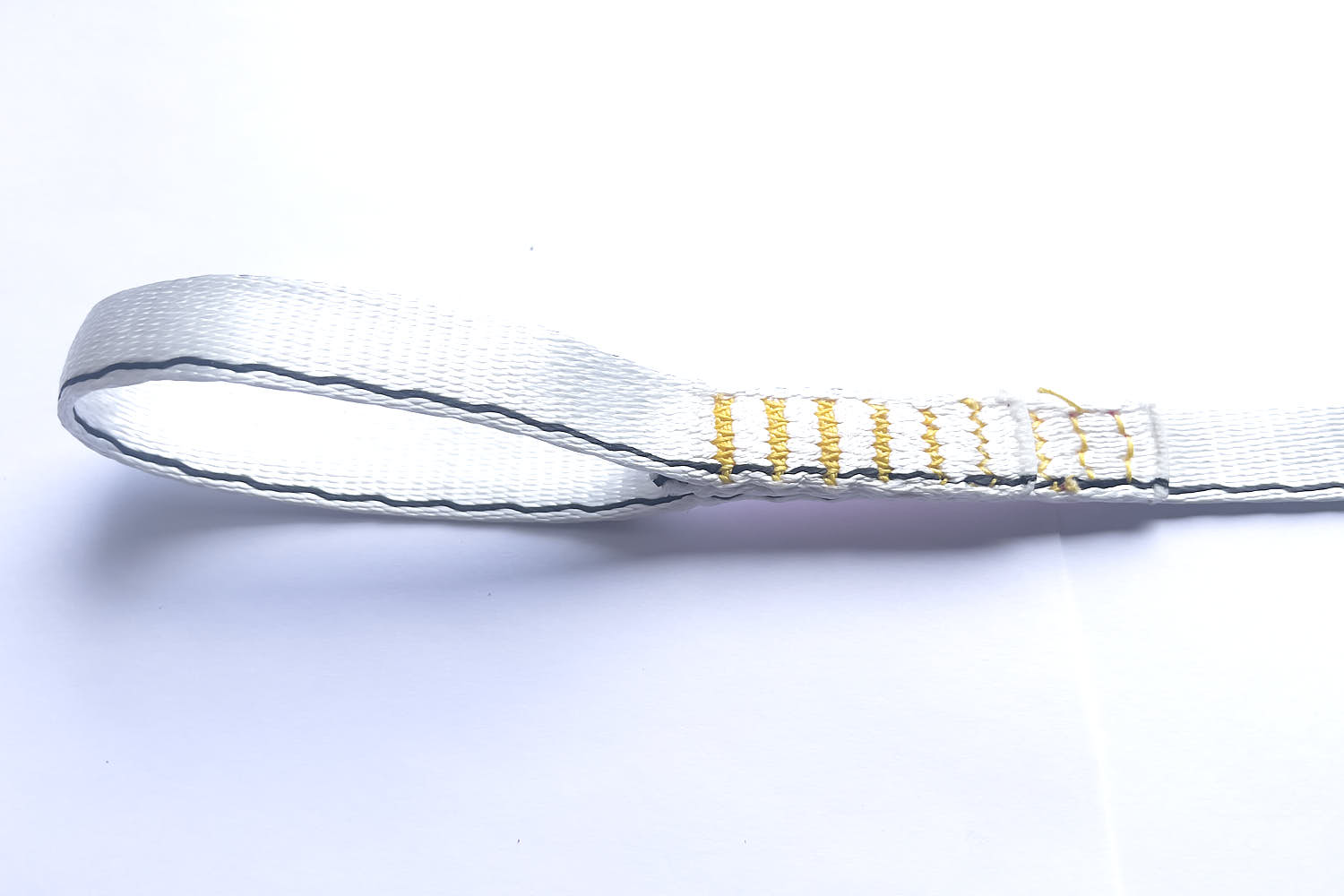

The High-Tech Only design is not only for the webbing, this includes the sewn loops! We exclusively sew our sewn loops on Silk 99 with Dyneema sewing thread. This gives us the ability to shrink the sewing patch to just 50mm long, making the sewn loops VERY compact.

Not only that, but we now have the option to do Naked sewn loops, which is a sewn loop without a protective sleeve (pictured above). Since this webbing will live in the middle section of highlines (more on this down below), the sewn loops will likely always be used at a segment connection. These spots in a big-line are prime suspects for unwanted oscillations. That's mainly due to the regular frequency of weight hotspots.

Most sewn loops on slackline webbings have a big bulky protective sleeve, typically made from nylon tubular webbing, which is quite heavy. Both the mainline and the backup line have these sleeves. Plus, when using soft connectors to connect your segments together, there will also be a soft thimble inside of these bulky sewn loops. Then you have your connectors, which are typically soft shackles or quicklinks. That's a TON of weight all in one little spot. With a webbing that is as light as Silk 99, these weight hot-spots can be very noticeable.

This is why we have opted to offer a naked sewn loop option. This brings the weight of your connection down by a staggering 50+ grams (assuming naked loops on main and backup). It also allows us to shrink the size of the sewn loop. We are able to fold over just 175mm of material, giving roughly a 125mm opening in the loop, which is plenty to assemble a segment connection.

These changes to the sewn loop make it possible to build a segment connection that weighs just 39 grams! That includes the extra webbing that's folded over for the sewn loop, the booster layer, 2x grog sling connectors (3mm D12 99 MAX, double-wrapped), and 2 webbing thimbles. Incredible and completely unnoticeable while walking.

Please note, we are continuously working on our sewn loop designs. The sewn loop you receive with your webbing may look different than the one in the picture above. Whatever sewn loop you receive is our current best/strongest design.

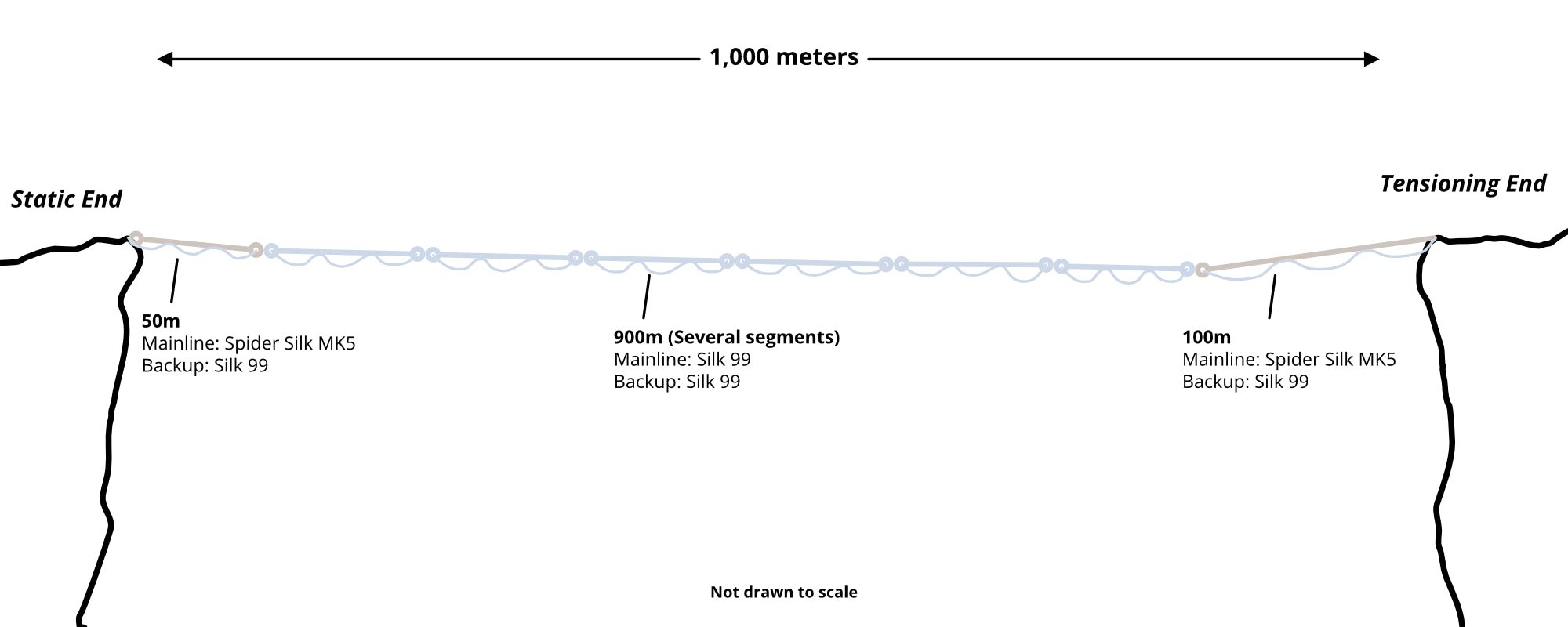

Silk 99, being a full HMPE webbing, has trouble being paired with hardware. This includes webbing anchors (weblocks and line-locker rings) and webbing grips (LineGrip, Wafer, Wafer XL, etc...). For this reason, we have built Silk 99 with the intention that it would be used as a part of a bigline composition.

What that means is that Silk 99 should not be used for the entire length of a big line. At the ends of biglines, you see a lot of interaction with both humans and hardware. These areas of the line should be built with a sturdy, hardy, hardware-compatible webbing, such as most higher strength low tech webbings, or Spider Silk MK5. These areas of biglines should NOT be rigged with Silk 99.

Silk 99 is meant for the body of a bigline project. For example, let's say we are rigging a 1,000 meter long highline and we want to use Silk 99 for the mainline and backup line for most of the gap. Our recommended segment composition for this type of line would be as follows (static side on left, tensioning side on right):

50m Spider Silk MK5/Silk 99 Backup -> 900m Silk 99/Silk 99 Backup (100m segments) -> 100m Spider Silk MK5/Silk 99 Backup

Now, for the bulk of the line, we have a very lightweight main/backup combo that is excellent for walking. The only interaction it will have is with feet and hands while walking and whatever connectors you decide to use for connecting segments together. The ends of the line, where you will be gripping, tensioning, and handling the webbing the most during rigging and derigging are built with a robust hardware-compatible webbing. Now you have no worries about slippage in devices while retaining the lightweight characteristics you are after for the best bigline experience.

So, when purchasing Silk 99 for your bigline projects, we recommend at least 2 segments of Spider Silk MK5 to use on each end. It's a good idea to have one that is 50-60m long for the static side and one that is 100m long for the tensioning side. If you plan to tension on both sides, go with 2x 100m segments of Spider Silk MK5.

Silk 99 is not compatible with any weblock. It will slip in all weblocks in a single-wrap configuration. When double-wrapped in a weblock, it will bend your front pin starting at around 24 kN, depending on the size of your front pin.

Silk 99 is not compatible with any line-locker ring. It will slip in a normal wrapped line-locker and will bend or break the pin of the shackle starting around 24 kN, depending on the diameter of the shackle pin. If line-locking is a must on Silk 99, we recommend double-wrapping a MightyLock on a Van Beest 1/2" (2-tonne) shackle, on the pin side.

Silk 99 is not compatible with any webbing grips. It will slip in micro grips starting at 2 kN. It will slip in full-size grips starting at 7 kN. If you absolutely must grip Silk 99, it is recommended to use a Wafer XL, which slips at 9 kN. Do not exceed 3 kN on a gripped Silk 99 and do not rely on this grip to hold tension on the line. ALWAYS have a backup in place.

Silk 99 is not meant to be used as a longline webbing without another piece of webbing to be used as the tensioning segment. The only reliable way to anchor Silk 99 is to use the provided sewn loops.

When using soft connectors on the sewn loops of Silk 99, a soft thimble (short piece of sturdy webbing roughly the same width as Silk 99) must be used between the soft connector and the sewn loop. Without a soft thimble, soft connectors can reduce the strength of the sewn loop by as much as 50%!

When walking Silk 99, it is recommended to use foot protection in order to maintain the best grip on the webbing. We recommend Skinners.

Width – 19.0 mm (0.75 inches)

Thickness – 1.45 mm (0.06 inches)

Weight – 19 g/m (1.28 lbs/100 feet)

MBS – 40.0 kN (9,000 lbf)

WLL – 13.3 kN (3,000 lbf)

Strength in AWL4 – Slips < 8 kN

Strength in AWL5 – Slips < 8 kN

Strength in AWL6 – Slips < 8 kN

Strength in MightyLock – Slips < 20 kN

LineGrip Slippage – Slips at 7 kN

Wafer XL Slippage – Slips at 9 kN

Wafer Slippage – Slips at 2 kN

MBS – 35.0 kN (7,868 lbf)

Thread Type – 210 Tex Dyneema Stitching

Raw Materials – Dyneema SK99 & Black HMPE

Weave Structure – Single layer weave

Weave Zoning – Single zone weave

Style – Optimized for walking big lines with relative ease

Optimum Tensions – 1.0 - 4.5 kN (225 - 1,000 lbf)

Preferred Lengths – 200+ m (660+ feet)

Approved – Yes

Backup Length – How long should the backup be with a Silk 99 mainline?

1 kN – 0.23%

2 kN – 0.69%

3 kN – 1.04%

4 kN – 1.29%

5 kN – 1.57%

6 kN – 1.73%

7 kN – 1.86%

8 kN – 2.07%

9 kN – 2.17%

10 kN – 2.24%

11 kN – 2.39%

12 kN – 2.53%