You have no items in your shopping cart.

0

You have no items in your shopping cart.

| Stretch | 5.92% @ 6kN |

| Material | Polyester (PES) |

| Weight | 55 g/m (3.70 lbs/100 ft) |

| MBS | 26.0 kN (5,845 lbf) |

| WLL | 5.2 kN (1,169 lbf) |

Style

Best Tension

Jelly PRO is due to be back in stock this Fall (2024)

Born from the BREATHE festival, the Jelly PRO webbing is here to inspire community, connection, purpose and motivate individuals to achieve their highest potential. Learn more about the BREATHE Festival at www.discoverbreathe.com

So you liked walking Jelly huh? Smooth on the foot, playful, bouncy, but easy to rig? Well, what if I told you there was a stronger, yet just as playful version of the stuff. Strong enough that you could take it up high...

Say hello to Jelly PRO, a 26 kN strong, 55 g/m light , mid-stretch webbing that literally feels like clouds beneath your feet. A tubular woven polyester webbing with an array of magnificent colors that dance before you while you float above it.

If you walk slacklines, this is the webbing for you.

Jelly PRO is made with a tubular weave. This gives the webbing two independent layers of material: one on each side. When Jelly PRO is tensioned, a small air gap forms between these two layers, adding a sort of air cushion in the webbing. This feels remarkable on the foot. After each step, the layer of material that your foot is on morphs slightly around the protrusions in your foot, giving support and comfort.

One of the main reasons that Jelly PRO has this small separation between the layers under tension is due to the thickness of the webbing. Jelly PRO is based on a legacy webbing called Jelly from Balance Community. A 20 kN polyester tubular webbing. We took that design and added about 20% more material. A good portion of that added material went into the edges, adding thickness to the weave.

p>As the tension in the webbing increases, the two faces of the webbing become slightly more rigid, allowing the true thickness of the webbing to take form. Jelly PRO under no tension has a thickness of 2.8mm. Under tension, that thickness grows to 7.0mm, more than DOUBLE!

We took the design of our legacy webbing Jelly, which had just pink and blue in a similar bar format, and we added a white stripe on one edge. This color change serves two purposes:

1.) To distinguish the pro status of this webbing. The previous generation was far too weak and fragile to be used beyond a simple park line. Jelly PRO is quite a bit stronger and more robust, giving it the promise of being used on highlines. We needed a clear way to tell the difference between these two webbings.

No White Stripe? No Highline!

2.) To make the Blue POP! The blue on our previous color design was quite dull and didn't really stand out. When the Blue pops, it makes the contrast with the pink all that much more. This webbing really pops under your feet.

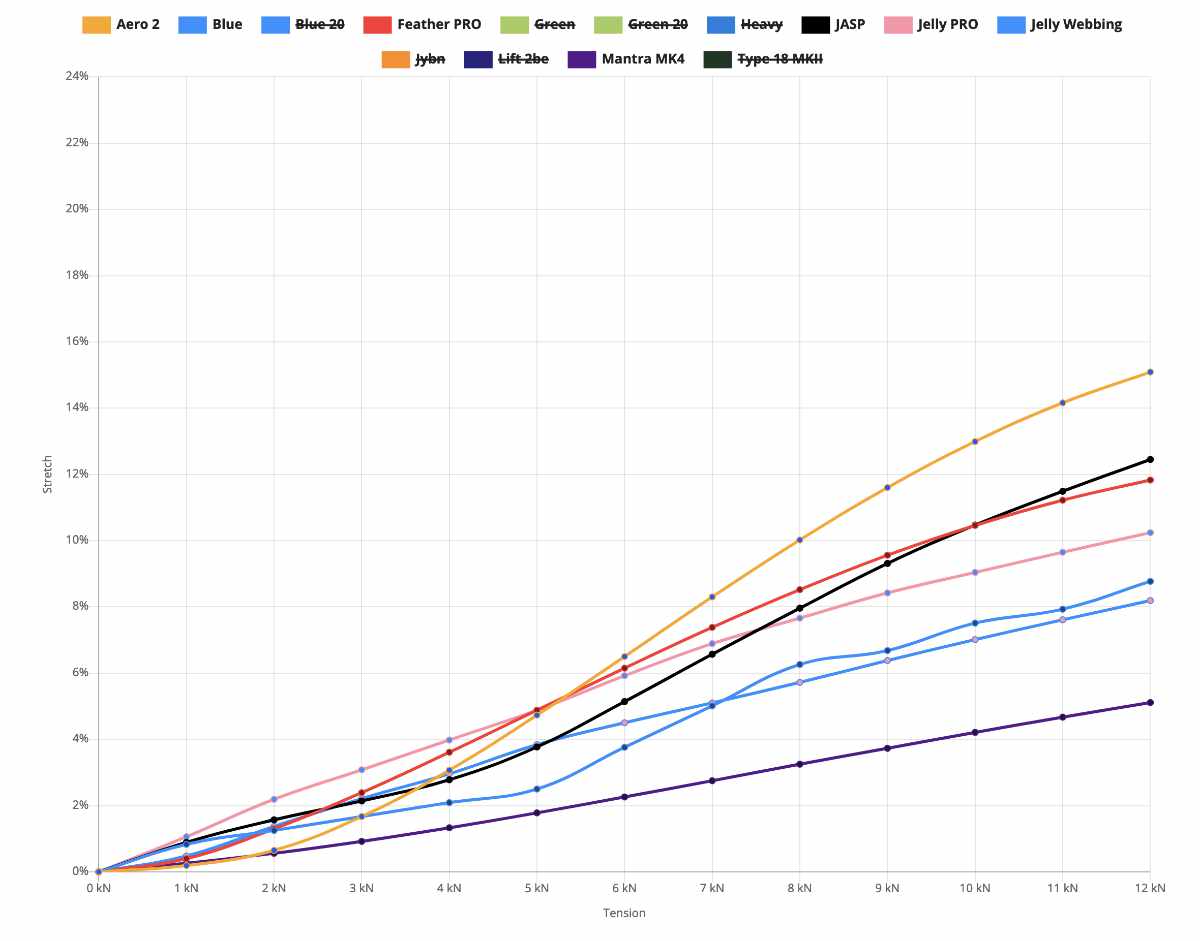

As the tension increases, Jelly PRO kind of levels out where most polyester webbings do. However, in the working tensions, between 1 kN and 4 kN, Jelly PRO is quite a bit stretchier than any of our other polyester webbings, including the previous generation of Jelly!

Here is a picture showing all of our polyester webbings on a single chart. Jelly PRO is the pink line.

This higher stretch at working tensions make Jelly PRO an excellent line for mid-length highlines and park mid-to-long length lines.

Compare the stretch of Jelly PRO to our other webbings on our Webbing Stretch page

Jelly PRO will be our first production webbing to use our new Bartack Ramp sewn loop pattern. A method that we have developed here in-house for slowly ramping up the densing of the bartacks within the sewn loop.

Traditionally, a sewn loop made with several bartacks has a weak point at the very first stitch. This is mainly due to an abrupt increase in density in the woven substrate. The webbings fibers are forced to deviate substantially across the entire width of the webbing due to the introduction of the sewing thread. By lowering the density of the sewing towards the front of the bartack set, and slowly increasing the density as you move along the stitch pattern, we can allow a much smoother deviation for the webbing fibers. This results in a much higher strength retention.

Our current pattern design for Jelly PRO retains roughly 88% of the strength of the webbing. We are continiously developing these patterns though and will strive to obtain 90 - 95% retention.

In addition to the new pattern, we are now using a stronger thread that is slightly larger. Our stitching is comprised of 207-lb polyester thread and we stitch a minimum of 300 stitches per sewn loop for maximum strength.

All fixed lengths (50m, 60m, 85m, 100m, and 120m) come with sewn loops on both ends included. Any custom lengths do not include sewn loops, they must be added to your order separately.

Width – 25.4 mm (1.00 inches)

Thickness – 2.80 mm (0.097 inches)

Weight – 55 g/m (3.70 lbs/100 ft)

MBS – 26.0 kN (5,845 lbf)

WLL – 5.2 kN (1,169 lbf)

Abrasion Retention – 0.6

MBS – 23.0 kN (5,170 lbf)

Thread Type – 207-lb Bonded Polyester

Raw Materials – 100% Polyester

Weave Structure – Tubular weave with color zones

Weave Zoning – Fully tubular design with soft edges and 5 color stripes across the width

Style – Great for short, easy to rig park lines and equally great for short to long highlines

Optimum Tensions – 1.0 - 4.5 kN (225 - 1,000 lbf)

Preferred Lengths – 30 - 200m (100 - 660 feet)

Approved – Yes

Backup Length – How long should the backup be with a Jelly PRO mainline?

1 kN – 1.06%

2 kN – 2.19%

3 kN – 3.08%

4 kN – 3.98%

5 kN – 4.88%

6 kN – 5.92%

7 kN – 6.89%

8 kN – 7.66%

9 kN – 8.42%

10 kN – 9.04%

11 kN – 9.65%

12 kN – 10.24%