You have no items in your shopping cart.

0

You have no items in your shopping cart.

| Stretch | 3.71% @ 6 kN |

| Material | Dyneema & Polyester |

| Weight | 26 g/m (1.75 lbs/100 feet) |

| MBS | 30.0 kN (6,744 lbf) |

| WLL | 10.0 kN (2,248 lbf) |

Style

Best Tension

After many months of research and development, several samples, and much testing, we have finally finished the design for Spider Silk MK4. This webbing offers quite a few benefits over our previous iterations, which we will discuss below.

Coming in at a weight of just 26 grams per meter, this webbing is one of the lightest high tech webbings on the market. Don't let the small weight fool you though, this webbing still packs an MBS of 30 kN, giving it an exceptional strength to weight ratio.

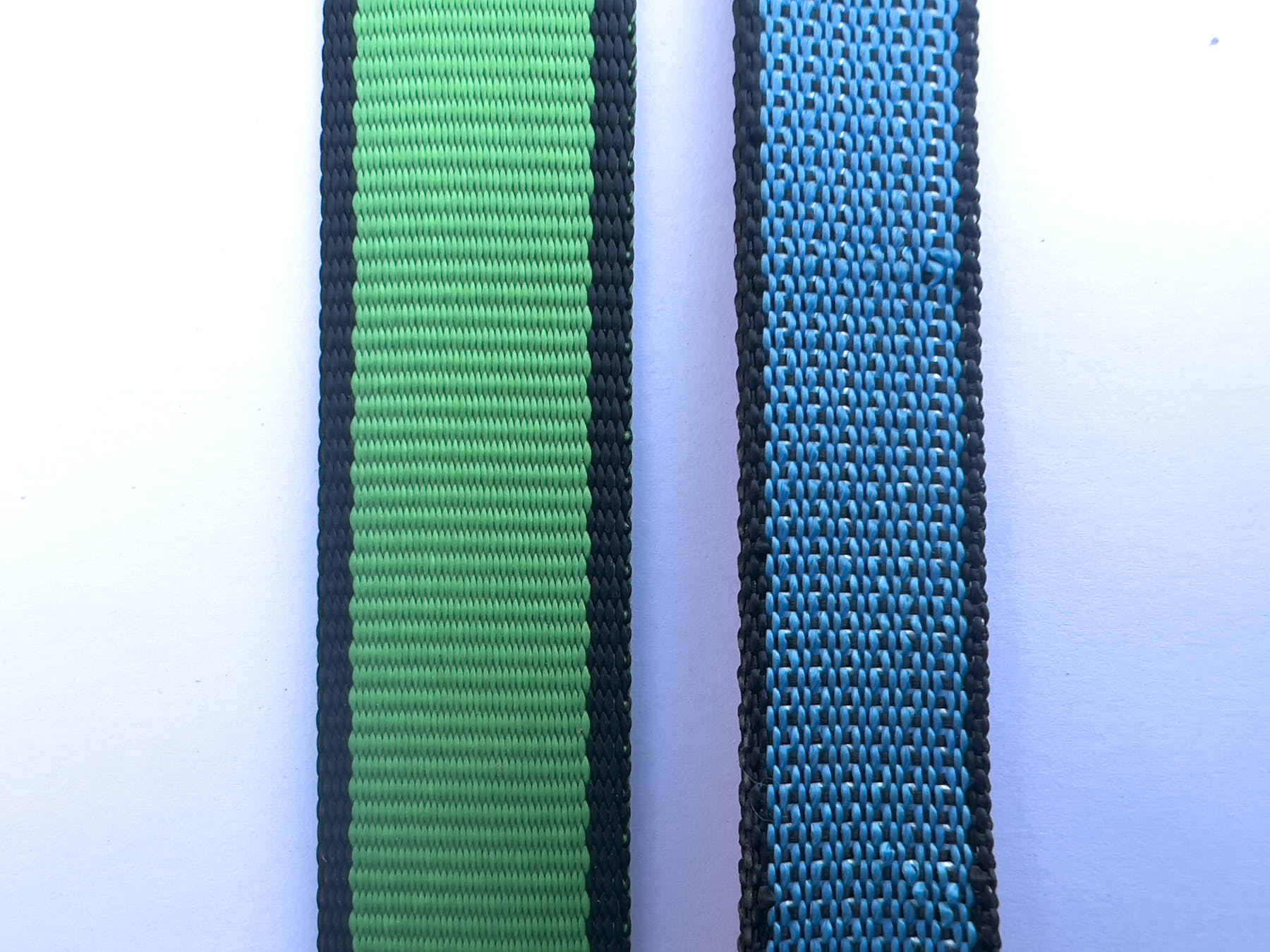

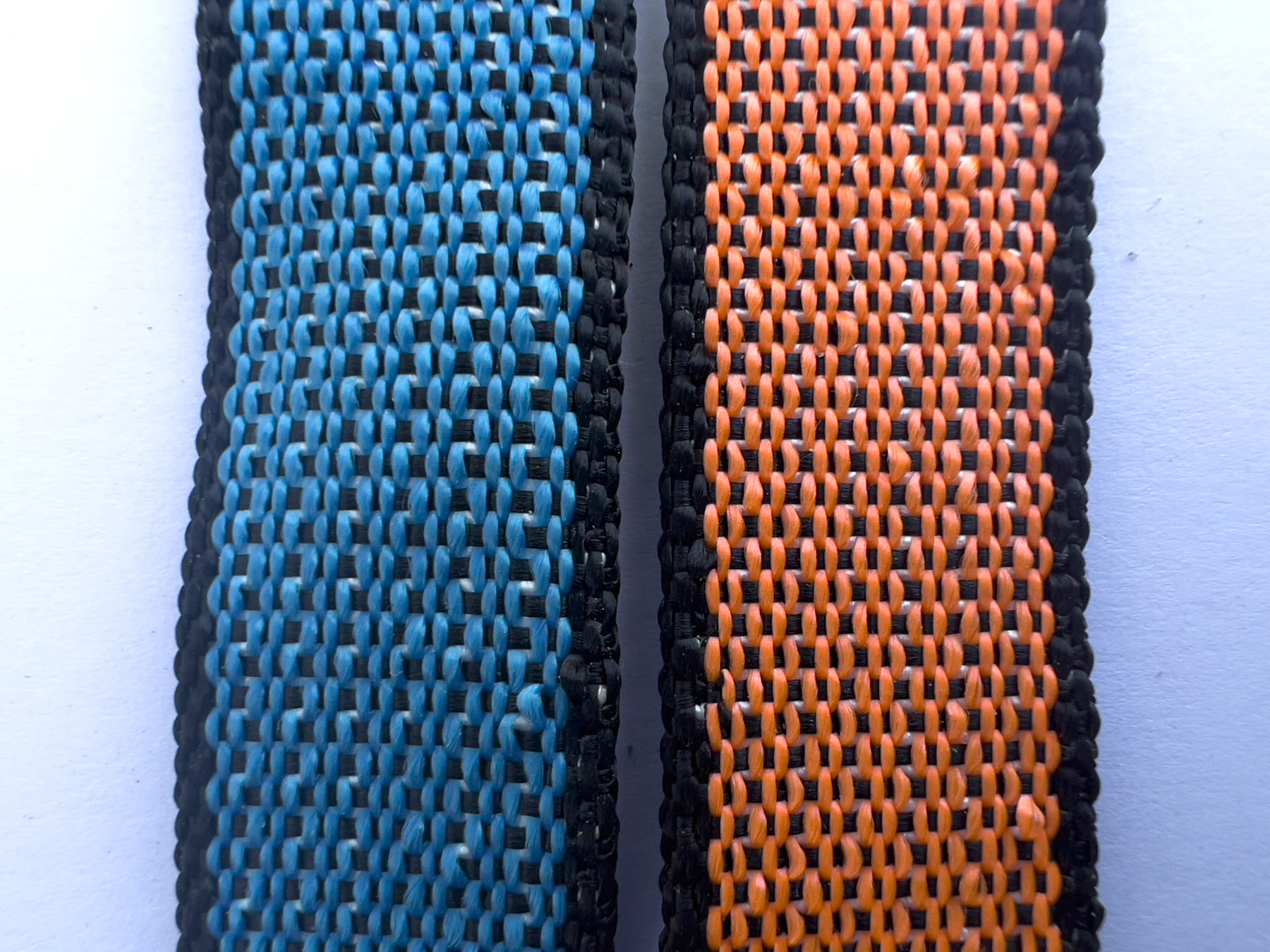

Not only does SSMK4 weight almost nothing, but it also sports a full polyester jacket! That's right, no high tech fibers are exposed on the exterior of the webbing, giving it incredible handling properties. You can grip it, you can weblock it, you can walk it with steep anchors, you name it! The face of SSMK4 acts like a standard slackline webbing, with the weight and strength properties of high tech. Quite amazing!

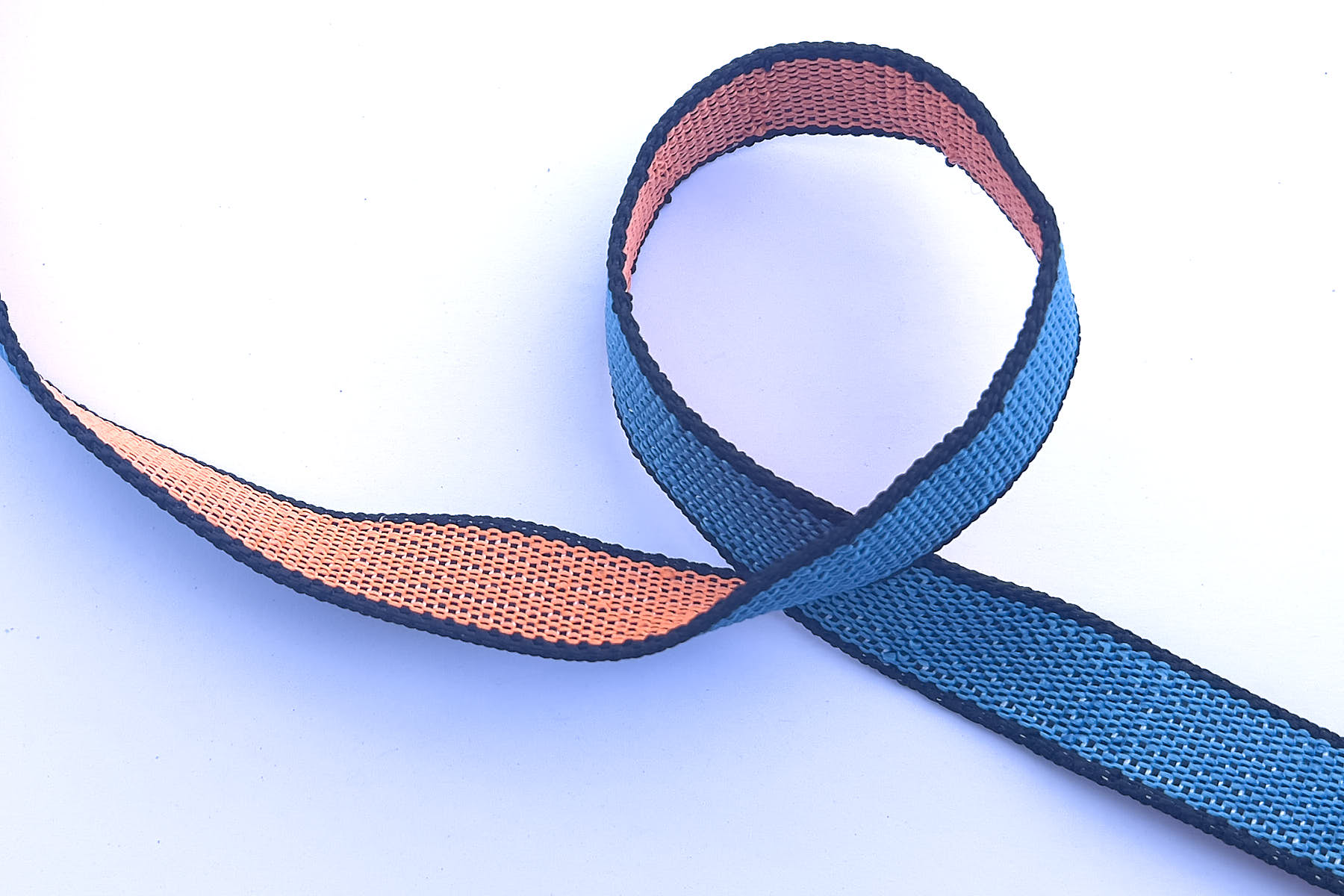

It doesn't stop there! On top of all this, we have designed SSMK4 to have a highly contrasting color scheme for very easy twist spotting on those monster lines. Orange on one side, blue on the other.

All of this in a 20mm wide package. Get ready to start cruising massive lines with ease!

Made in the US.

The beauty of high-tech webbing is that it can be so incredibly lightweight while still retaining a great amount of strength. We packed just about as much strength as we possibly could into this small webbing.

A typical low-tech webbing made from Nylon or Polyester will hover around a 0.55 strength to weight ratio. Spider Silk MK4 comes in at 1.15! That is insane! This ratio is impossible with standard highline webbings. We were able to achieve it even when having a full low-tech sheath on the webbing, which contributes nothing to the strength (essentially dead-weight).

Wind is a serious problem on longer highlines. Flat (or even tubular) webbing acts as a sail to the wind that is flowing over a highline. This can cause major problems if the winds are high enough. Tapes start to rip, lines start flapping, and the main and backup start smashing into each other. This can lead to a complete highline failure, as we have seen many times in many places.

One way to look at how wind interacts with the slackline is to look straight down. Given a set length, there is a certain amount of surface area that the slackline has over that length (length x width). Given that we are all going for longer and longer lines, this surface area is bound to get larger as our lines grow. The larger the surface area, the more the wind will hit your line. So, what if we reduce the width instead?

We played with a number of difference widths and found that 20mm is a nice sweet spot for still providing a stable platform on which you can stand/walk, while still reducing the overall surface area of webbing exposed to the wind. The 20mm era is upon us!

Not only is wind an important reason for making this webbing 20mm wide, but also the thickness! A very lightweight webbing at 1-inch wide is very very thin, causing the edges to be extremely sharp which also increases the likelyhood that the webbing will "taco", or fold in half across the width, causing even sharper edges to form. A 20mm width allows us to bulk up the thickness without adding weight to the final substrate. A win all around.

On all the exposed faces of Spider Silk MK4, you will see Polyester fibers. One one face you have a vivid blue color. On the opposite face, is a bright orange color. The edges are black. These Polyester yarns don't do anything for the strength of this webbing, however, they provide an interface for the webbing to work with all our hardware. From weblocks to webbing grips, Spider Silk MK4 gives you compatibility with the hardware you already have.

Not only does the Polyester Jacket help with hardware compatibility, it allows us to add some vivid colors to this webbing to aid in visibility for monster lines. One side is Orange and the other is Blue, giving a very high contrast. This is helpful for spotting the line while walking, detecting twists, and visibility for external forces (aircraft, mainly).

Width – 20.0 mm (0.79 inches)

Thickness – 2.00 mm (0.08 inches)

Weight – 26 g/m (1.75 lbs/100 feet)

MBS – 30.0 kN (6,744 lbf)

WLL – 10.0 kN (2,248 lbf)

Strength in AWL4 – 27.0 kN (6,070 lbf) - Must use spacers

Strength in AWL5 – 22.0 kN (4,946 lbf) - Must use spacers

Strength in AWL6 – 30.0 kN (6,744 lbf) - Must use spacers

Strength in MightyLock – 27.0 kN (6,070 lbf) - Must use 20-22mm jaw-width shackle

LineGrip Slippage – Not compatible

Wafer XL Slippage – Not compatible

Wafer Slippage – Not compatible

MBS – 25.0 kN (5,620 lbf)

Thread Type – 208-lb Bonded Polyester

Raw Materials – Hybrid Blend - Dyneema and Polyester

Weave Structure – 3-layer Weave with full Polyester Jacket

Weave Zoning – Three-Zone Construction with Strength and Protective Zones

Style – Optimized for walking big lines with relative ease

Optimum Tensions – 1.0 - 4.5 kN (225 - 1,000 lbf)

Preferred Lengths – 100+ m (330+ feet)

1 kN – 0.64%

2 kN – 2.0%

3 kN – 2.7%

4 kN – 3.12%

5 kN – 3.47%

6 kN – 3.71%

7 kN – 3.93%

8 kN – 4.11%

9 kN – 4.25%

10 kN – 4.4%

11 kN – 4.49%

12 kN – 4.67%