Introduction

I have been slacklining for almost 7 years right now and still some of my favorite webbings are threaded models. I think my all time favorite is 1" Threaded Slack-Spec Tubular which is improved (stronger and more dynamic) version of classic 1" threaded tubular webbing. Recently I expended my slackline pile with other threaded models like RAGEline (1.25" polyester tubular webbing with Type 18 MKII inside), PowrLine (1" Slack Spec Tubular inside1 ¼" Tubular Webbing) and VecTec (7/8" Spider Silk inside 1" Slack Spec Tubular).

There are lots of reasons why I do like these lines but redundancy, round edges and good dynamics and strength are most important to me. If you didn't get the lines in one piece nice and threaded you are going to have some fun. Over many years I threaded quite a few lines but never had too much experience with it. I also tried different tools and methods but just recently learned a really good method from Jerry Miszewski himself. This guy has tons of experience with threading the lines in huge amount as he runs his own slackline company Balance Community. I had a chance to test these methods by myself. In less than one day Jerry and I threaded over 4000 feet of RAGEline and my new 55m piece of VecTec. Obviously both of us were tired afterward but we had a good rhythm and everything worked really well. Naturally, normal users will thread one line at the time so we'll focus on this (we can skip organizing multiple lines in boxes etc).

Methods

There are two main methods to thread your line:

- The first method is when you thread the webbing directly by using a metal stick (this method works for most situations except for when threading VecTec and really long pieces of RAGEline)

- The second method involves threading a long piece of cord inside your tubular webbing first and then pulling the inner webbing through with the cord.

Method 1

What you will need:

- 2 Tree-Protectors

- 1-2 slings

- 2-3 carabiners

- A threading stick (best is around 2 meters length) with a piece of thin cord (best option I found is lash-it cord from Samson Ropes)

- Splicing fid (optional)

- Pliers

THE STEPS

- Cut the end of the outer tubular line along the length. The cut should be around 20-25cm long down the center of the webbing. When you are done, slightly melt the edges of the cut to prevent it from fraying.

- Stuff the inner line inside your haulbag, box or BC LineBag. While doing that, try to remove all the twists from the line.

- Pack the outer and inner line and the rest of your equipment and go to the park.

- Find a shaded spot with a nice tree to attach to (it is better to thread your line hidden from the sun so that it doesn't get to hot; this leads to more friction in between the lines making the whole process more difficult).

- Find a nice tree in the shaded area and wrap two Tree-Protectors around it at about waist height.

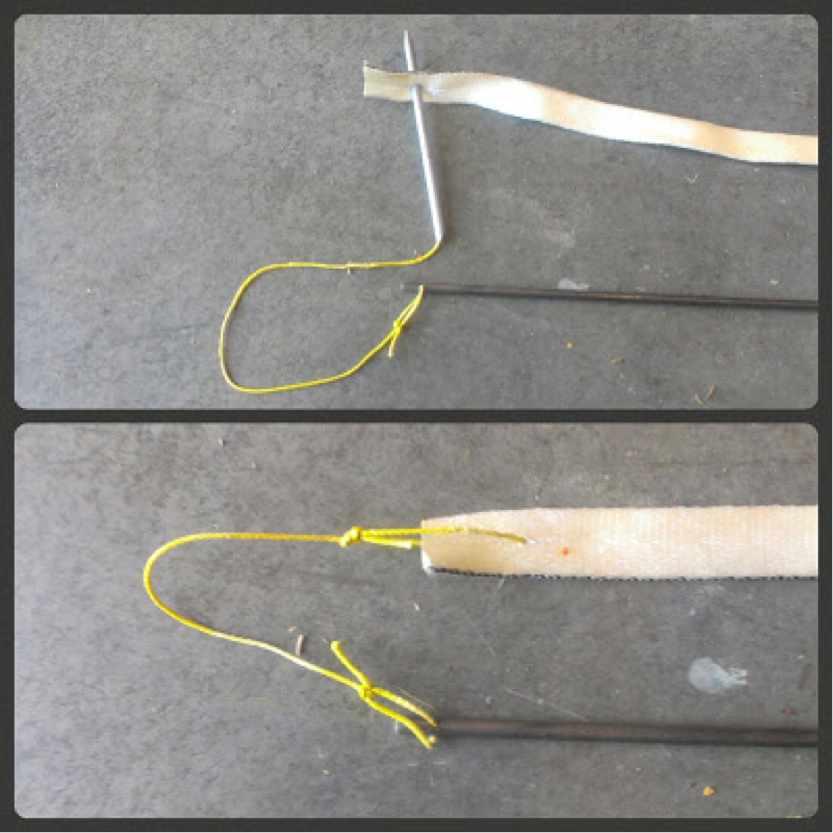

- Attach the threading stick to the inner webbing (in order to do that, use the splicing fid or something similar to thread the thin cord from the threading stick through the inner webbing at about 2-3cm away from the end).

- Put the threading stick inside the outer webbing and thread the inner webbing through a short distance (2-4 meters)

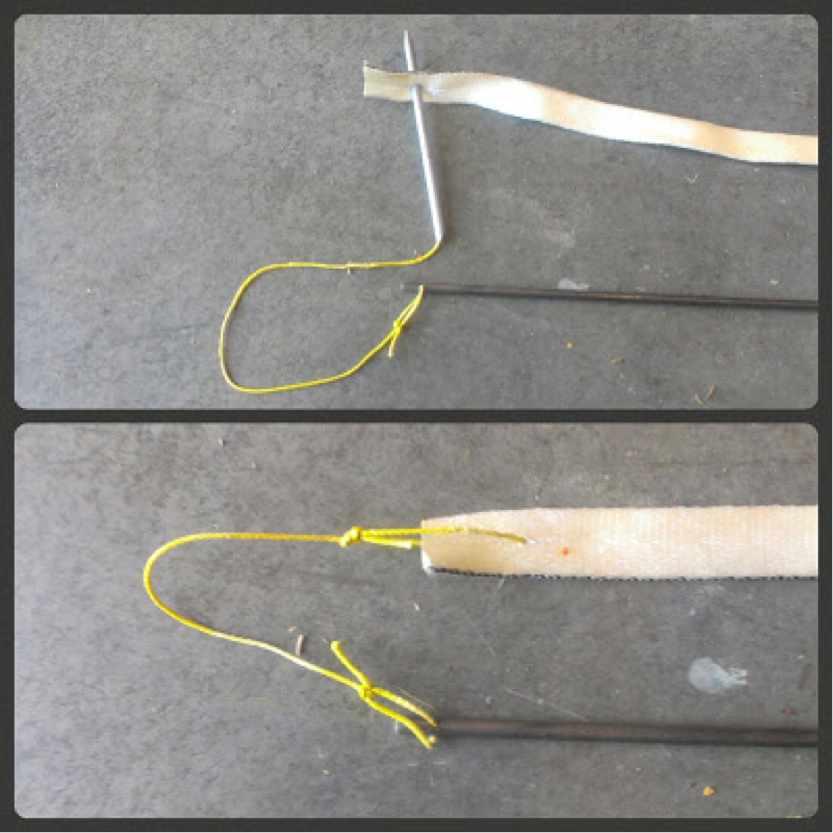

- Wrap the first sling around the higher Tree-Protector and tie the ends of the split outer webbing to the sling ends, as shown in the picture below.

- Stretch the outer webbing on the ground, making sure it is in-line and has no twists.

- Clip the inner webbing through a carabiner placed on the Tree-Protector and the sling as shown in the picture below (this should prevent any twists from entering the outer webbing).

- Start threading the inner webbing through the outer. What works best for me is to support the end of the threading stick inside the outer webbing on my foot or the ground and then push the outer webbing down while making sure you don't get any twists. Do this until the threading stick is full of creased webbing and then slowly pull on it away from where the outer webbing is anchored. If there is lots of friction and you have problems pulling your threading stick through, make a small bend at the end of it or even full bend which creates a handle and then pull again.

- Continue this process until you thread the whole inner webbing through. If you're planning on melting the ends of your webbings together first pull the outer webbing with pliers to remove the creases along the length. If you want to leave the ends free tie a water-knot on each end of outer webbing.

Method 2

This method works best for long distances or in situations where there is a lot of friction in between the two webbings. If the friction is really bad (like in the case of VecTec) depending on your cord strength, you might want to double or even triple it and then pull the cord through with a pulley system in small increments.

What you will need:

- 2 Tree-Protectors

- 1-2 slings

- 2-3 carabiners

- A threading stick (best is around 2 meters length) with a piece of thin cord (best option I found is lash-it cord from Samson Ropes)

- Splicing fid (optional)

- Pliers

- A long piece of cord (a bit longer then your webbing length or double/triple if you need stronger option)

Additional gear for high friction situations:

- A pulley system (any size will do, but the more rope, the better)

- Handled ascender

- Sling + Tree-Protector

THE STEPS

- Cut the end of the outer tubular line along the length. The cut should be around 20-25cm long down the center of the webbing. When you are done, slightly melt the edges of the cut to prevent it from fraying.

- Stuff the inner line inside your haulbag, box or BC LineBag. While doing that, try to remove all the twists from the line.

- Pack the outer and inner line and the rest of your equipment and go to the park.

- Find a shaded spot with a nice tree to attach to (it is better to thread your line hidden from the sun so that it doesn't get to hot; this leads to more friction in between the lines making the whole process more difficult).

- Find a nice tree in the shaded area and wrap two Tree-Protectors around it at about waist height.

- Attach the threading stick to the threading cord.

- put your threading stick inside the outer webbing and thread the threading cord through a short distance (2-4 meters).

- Wrap the first sling around the higher Tree-Protector and tie the ends of the split outer webbing to the sling ends, as shown in the picture above.

- Stretch the outer webbing on the ground, making sure it is in-line and has no twists.

- Clip the inner webbing through a carabiner placed on the Tree-Protector and the sling as shown in the picture above (this should prevent any twists from entering the outer webbing).

- Start threading the cord through the outer webbing the same way described above.

- Attach the inner webbing to your threading cord and if it's possible to pull it through just with your hands, do that.

- If there is too much friction what you need to do is to find another tree spaced a bit further then the end of the webbing and attach the pulley system to it with the extra sling Tree-Protector. Then attach the threading cord to the pulley system with a very strong knot. Next pull the cord through until the pulley system is shortened. Extend the pulley system out again and then reset the knot on the cord. Repeat this process until the entire inner webbing is threaded through. Try to pull slowly and consistently without any rapid pulls, as they can increase the force and break the threading cord.

- If you're planning on melting the ends of your webbings together first pull the outer webbing with pliers to remove the creases along the length. If you want to leave the ends free tie a water-knot on each end of outer webbing.

Discussion

I hope this post helped you to understand and mastering the threading technique. Next tutorial coming soon! This time on: how to set up a rodeo line.

Peace S SlackOn! Janek

← Older Post Newer Post →

0 comments