You have no items in your shopping cart.

0

You have no items in your shopping cart.

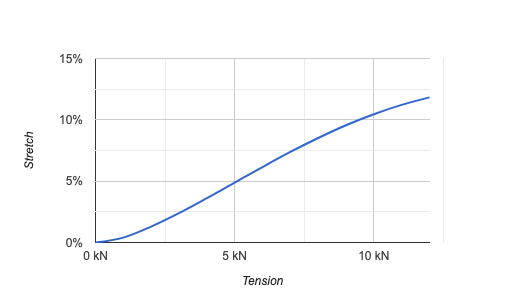

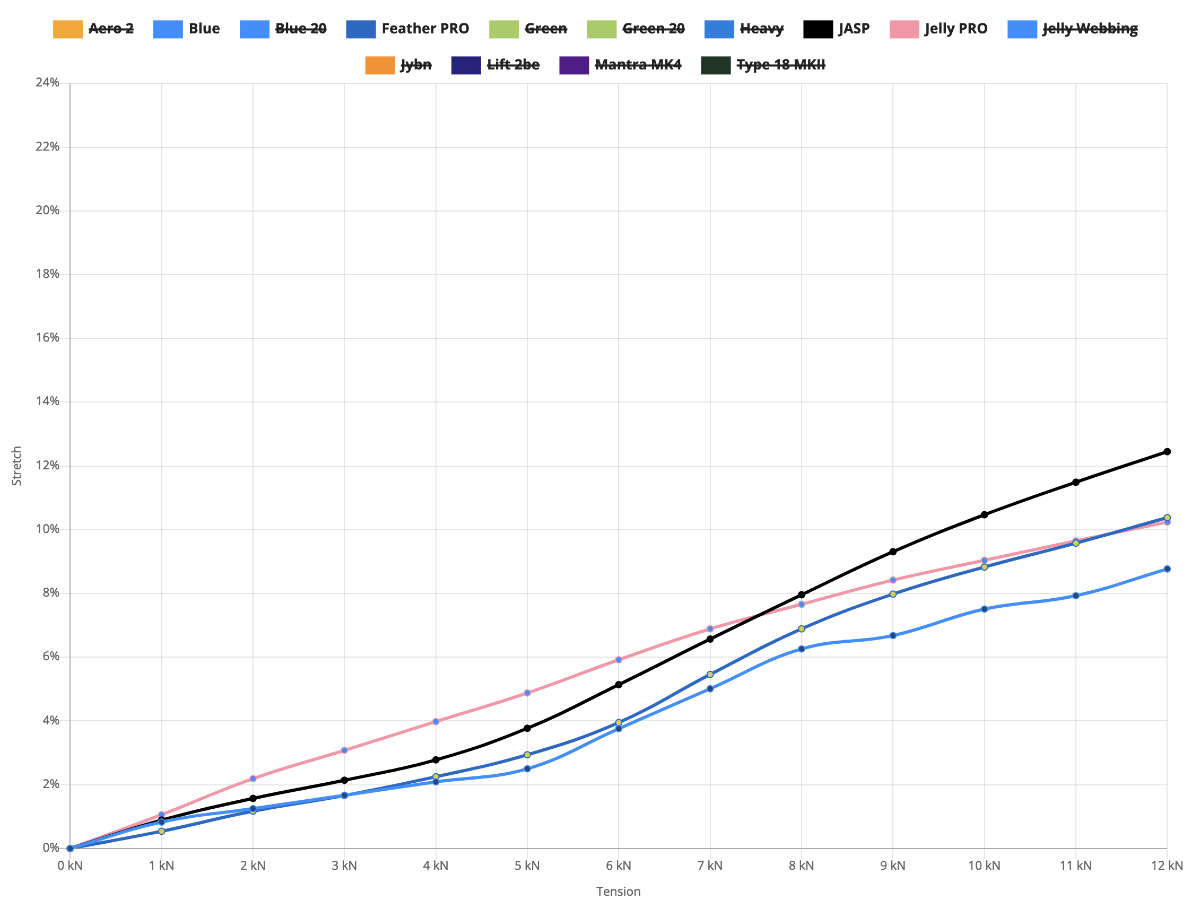

| Stretch | 4.36% @ 6kN |

| Material | Polyester (PES) |

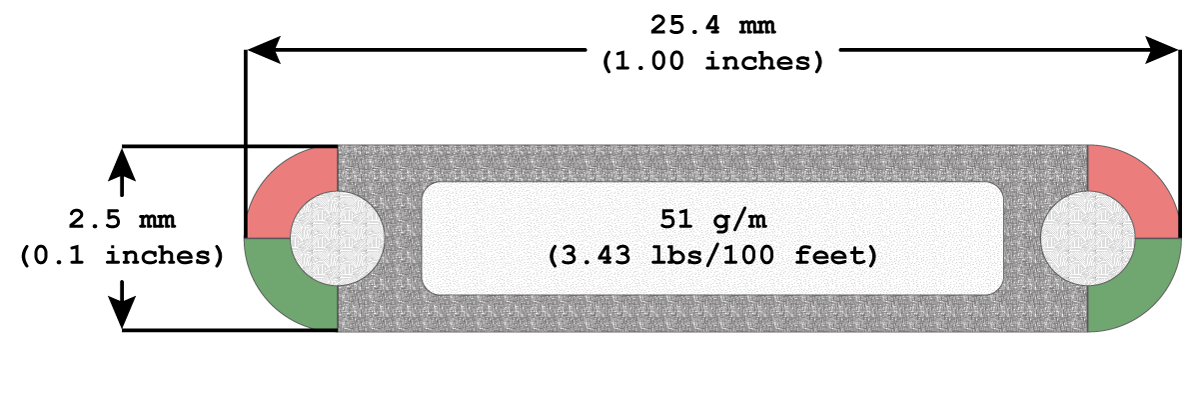

| Weight | 51 g/m (3.43 lbs/100 ft) |

| MBS | 26.0 kN (5,845 lbf) |

| WLL | 8.7 kN (1,948 lbf) |

| Width | 25.4 mm (1.00 inches) |

Style

Best Tension

Introducing an all new lightweight slackline made from 100% low-tech fibers. Feather PRO is a built with the low tension highliner in mind.

The webbing that was used to rig and walk a world record low-tech highline in France in 2017 that was 800m (2,624 feet) long. Boasting a strength of 29 kN and a weight of 51 g/m, this webbing has one of the highest strength-to-weight ratios out there.

Feather PRO is the perfect webbing for alpine projects, lightweight travel kits, and a plethora of other types of slacklines. Not only is Feather PRO optimized for weight and strength, it also features our signature Pillowed Edges as well as the tough LineSkin resin coating. These two features make Feather PRO a dream to walk and catch on highlines.

Made in the US.

Feather PRO weighs in at 51 g/m (3.43 lbs/100 ft) with a strength of 26.0 kN (5,845 lbf). This gives Feather PRO an extremely high strength-to-weight ratio, packing the maximum punch in the smallest package. This ensures an easy hike in and a confident walk on the line.

With packability and ease of carrying a priority in the design of Feather PRO, we shot for as low weight as possible while maintaining a healthy MBS. Combine the low weight with all the other amazing features Feather PRO has and you get a world class highline webbing built for big lines and alpine missions.

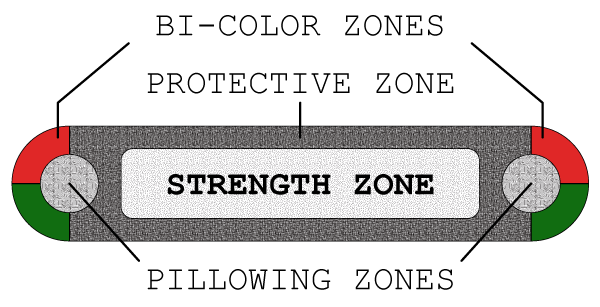

At the core of Feather PRO lies the Strength Zone, where the majority of the 26.0 kN (5,845 lbf) strength comes from. Built using high tenacity polyester fibers, this zone has been purely optimized for raw strength to get the most out of these quality PES fibers.

A protective layer surrounding the core and pillowing, the Protective Zone is built from less strong but more abrasion resistant Polyester fibers to ensure the sensitive core is protected while the line is under tension. The Protective Zone sees part of the load while tensioned, but contributes less to the overall strength of the webbing compared to the Strength Zone. However, the majority of the abrasion resistance of Feather PRO is a direct result of this tightly woven Polyester layer.

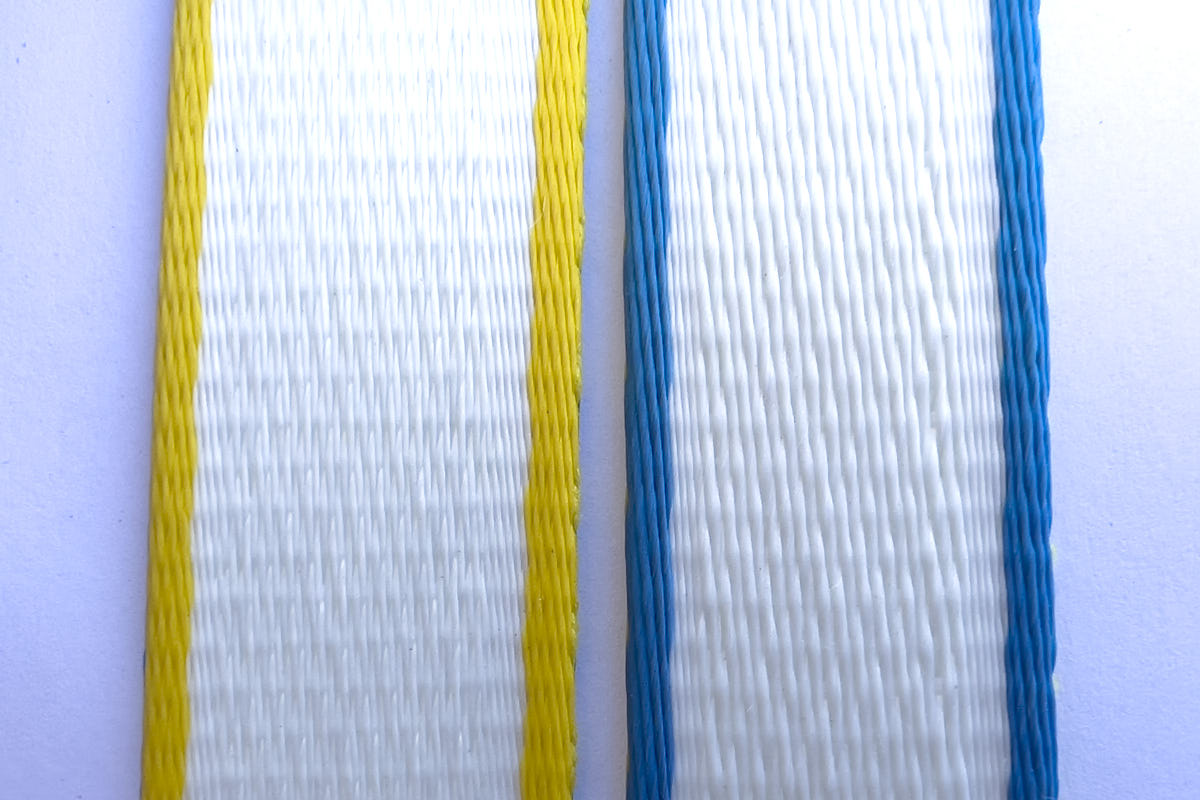

An innovative and sleek way of make twist detection a breeze. The Bi-Color zones have opposing colors on the edges of both faces to make it easy to spot any twists along the length of the line. We find it's easiest if the dark green color is up, as you can see red spots along the length very easy this way. These colored edges are made from high-tenacity, highly abrasion-resistant, solution-dyed, Polyester yarns to give the best of all worlds on one of the most sensitive parts of your slackline webbing.

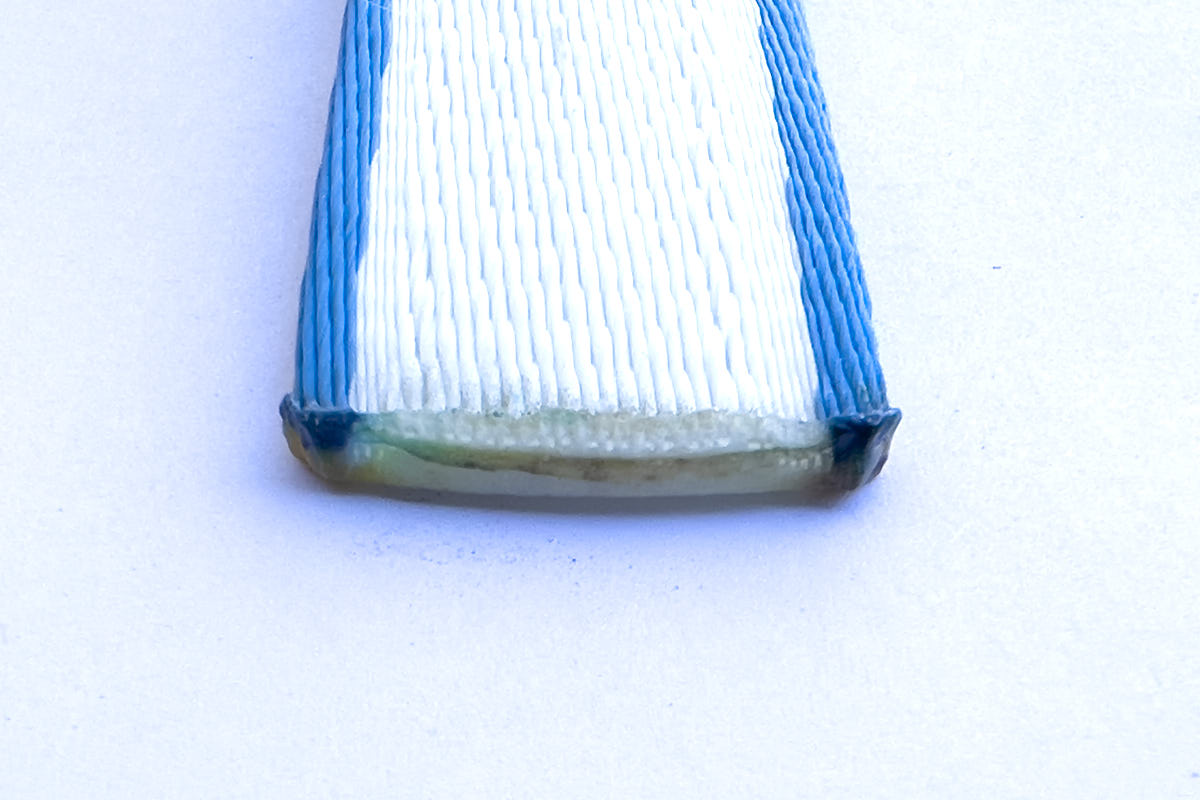

One of the most advanced features of Feather PRO is the Pillowing Zones. These zones are built from 100% nylon fibers which stay loose even when the webbing is under tension. This allows the edges to be pliable and malleable while the line is tight, which gives the edges a pillow-feel, molding under your hands and feet when you grab and walk on the line. This feature makes Feather PRO a true pleasure to interact with.

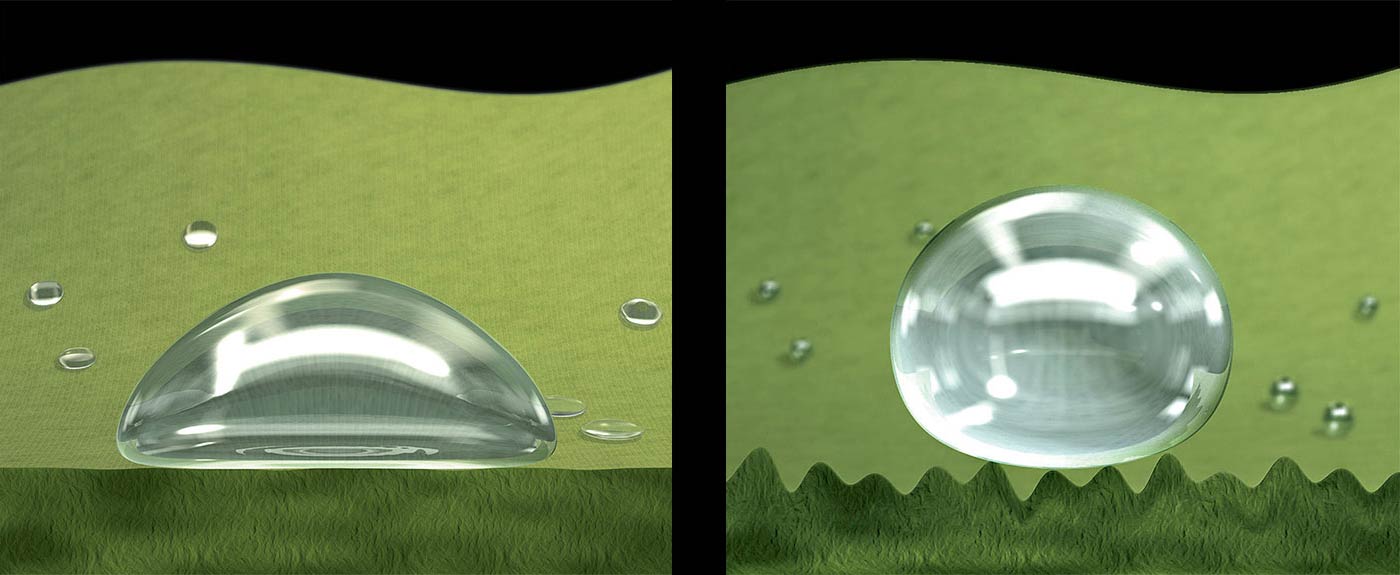

Once Feather PRO is finished being woven, we run it through a coating process where we apply our signature LineSkin Resin Coating. This is comprised of billions of nano particles that latch onto the individual monofilaments within the webbing.

Once LineSkin has been applied to the webbing, the surface of the individual filaments changes to a more ridged texture, which acts as a shield against both moisture and dirt particles. You will notice that webbings that have LineSkin applied actually will float on the top of water. This is due to the surface friction created by the LineSkin coating.

The ridged texture that each monofilament has once LineSkin treated now becomes significantly more abrasion resistant. Depending on the weave type, you can nearly double the abrasion resistance of the webbing simply by treating it with LineSkin resin coating. Feather PRO gains nearly 1,500 lbf of strength retention after the abrasion resistance test compared to a non-treated sample.

Feather PRO is made from 95% Polyester fibers, which are inherently low stretch and very dead feeling when under tension. However, the specific weave that Feather PRO utilizes maximizes the stretch of the fibers by utilizing some of the mechanical stretch of the weave pattern. This results in one of the highest stretch polyester webbings on the market.

Not only does Feather PRO have a very high stretch curve for being a Polyester webbing, but the stretch curve has been optimized at the more normal tensions used for highlines. This means that Feather PRO has a very smooth stretch curve in the 1 - 6 kN (225 - 1,350 lbf) range. Usually a smooth and steep stretch curve results in more work to rig the line. Fret not as Feather PRO is considered "Mid-Stretch", which means it retains some of the low stretch properties of Polyester, making it easy to rig at length.

Due to the lower stretch of Feather PRO, it is recommended to only use it for highlines longer than 50m.

Compare the stretch of Feather PRO to our other webbings on our Webbing Stretch page

The sewn loop on Feather PRO will use our new Bartack Ramp sewn loop pattern. A method that we have developed here in-house for slowly ramping up the density of the bartacks within the sewn loop.

Traditionally, a sewn loop made with several bartacks has a weak point at the very first stitch. This is mainly due to an abrupt increase in density in the woven substrate. The webbings fibers are forced to deviate substantially across the entire width of the webbing due to the introduction of the sewing thread. By lowering the density of the sewing towards the front of the bartack set, and slowly increasing the density as you move along the stitch pattern, we can allow a much smoother deviation for the webbing fibers. This results in a much higher strength retention.

Our current pattern design for Feather PRO retains roughly 90% of the strength of the webbing. We are continiously developing these patterns though and will strive to obtain 90 - 95% retention.

In addition to the new pattern, we are now using a stronger thread that is slightly larger. Our stitching is comprised of 207-lb polyester thread and we stitch a minimum of 300 stitches per sewn loop for maximum strength.

All fixed lengths (50m, 60m, 100m, and 120m) come with sewn loops on both ends included. Any custom lengths do not include sewn loops, they must be added to your order separately.

Width – 25.4 mm (1.00 inches)

Thickness – 2.46 mm (0.097 inches)

Weight – 51 g/m (3.43 lbs/100 ft)

MBS – 26.0 kN (5,845 lbf)

WLL – 8.7 kN (1,948 lbf)

Abrasion Retention – 0.6

AWL4 Mean Strength – 25.0 kN (5,620 lbf)

AWL4 MBS – 23.3 kN (5,238 lbf)

AWL5 Mean Strength – 24.5 kN (5,507 lbf)

AWL5 MBS – 20.9 kN (4,698 lbf)

AWL6 Mean Strength – 25.8 kN (5,800 lbf)

AWL6 MBS – 24.0 kN (5,395 lbf)

MightyLock Mean Strength – 24.0 kN (5,395 lbf)

MightyLock MBS – 21.0 kN (4,721 lbf)

LineGrip Slippage – No slippage up to 150% of WLL (22 kN)

Wafer XL Slippage – No slippage up to 150% of WLL (15 kN)

Wafer Slippage – No slippage up to 150% of WLL (6 kN)

Mean Strength – 25.5 kN (5,732 lbf)

MBS – 23.4 kN (5,260 lbf)

Thread Type – 210 Tex Dyneema

Raw Materials – Hybrid Blend - 95% Polyester & 5% Nylon

Weave Structure – Flat Weave with Pillowed & TruRound Edges

Weave Zoning – Four-Zone Construction with Strength, Protective, Bi-Color, and Pillowed zones

Style – Optimized for walking with minor playfulness at the right tensions

Optimum Tensions – 1.0 - 4.5 kN (225 - 1,000 lbf)

Preferred Lengths – 50 - 400m (165 - 1,312 feet)

Approved – Yes

Backup Length – How long should the backup be with a Feather PRO mainline?

1 kN – 0.97%

2 kN – 1.61%

3 kN – 2.11%

4 kN – 2.67%

5 kN – 3.33%

6 kN – 4.36%

7 kN – 5.63%

8 kN – 6.59%

9 kN – 7.3%

10 kN – 7.92%

11 kN – 8.56%

12 kN – 9.12%